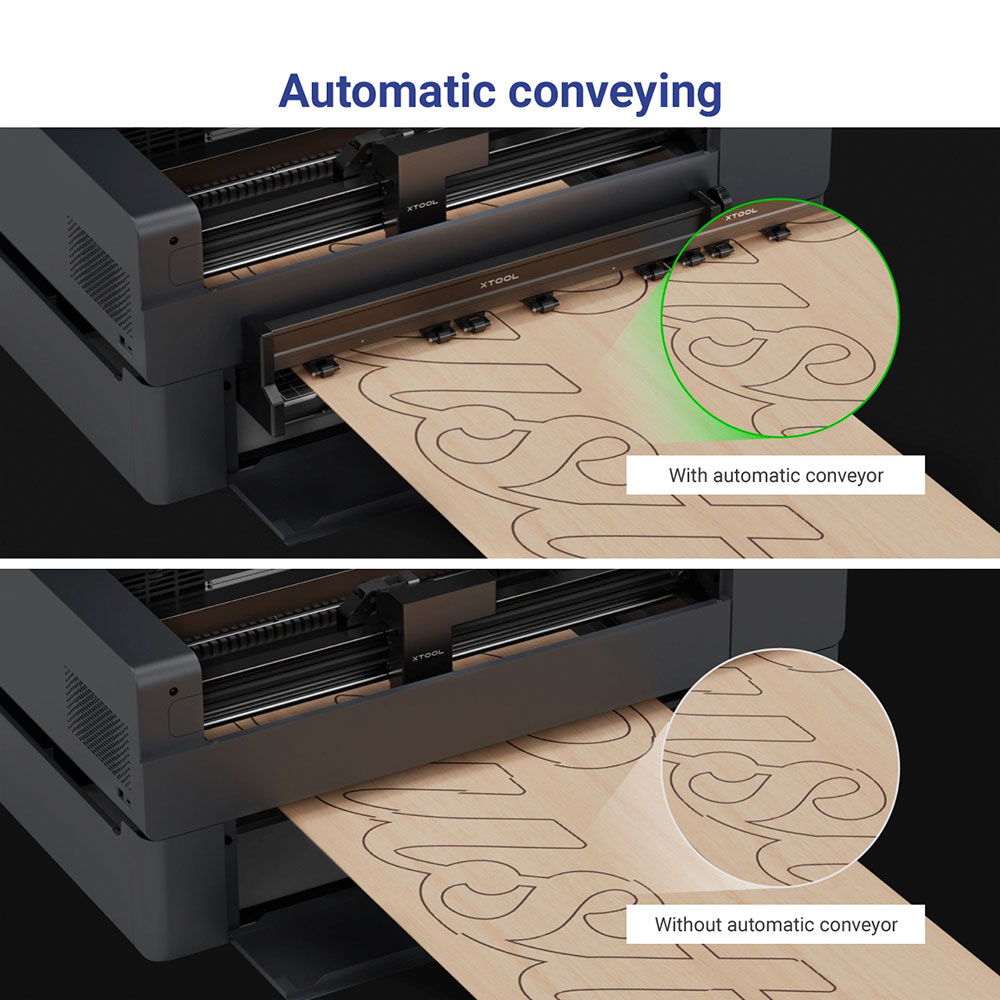

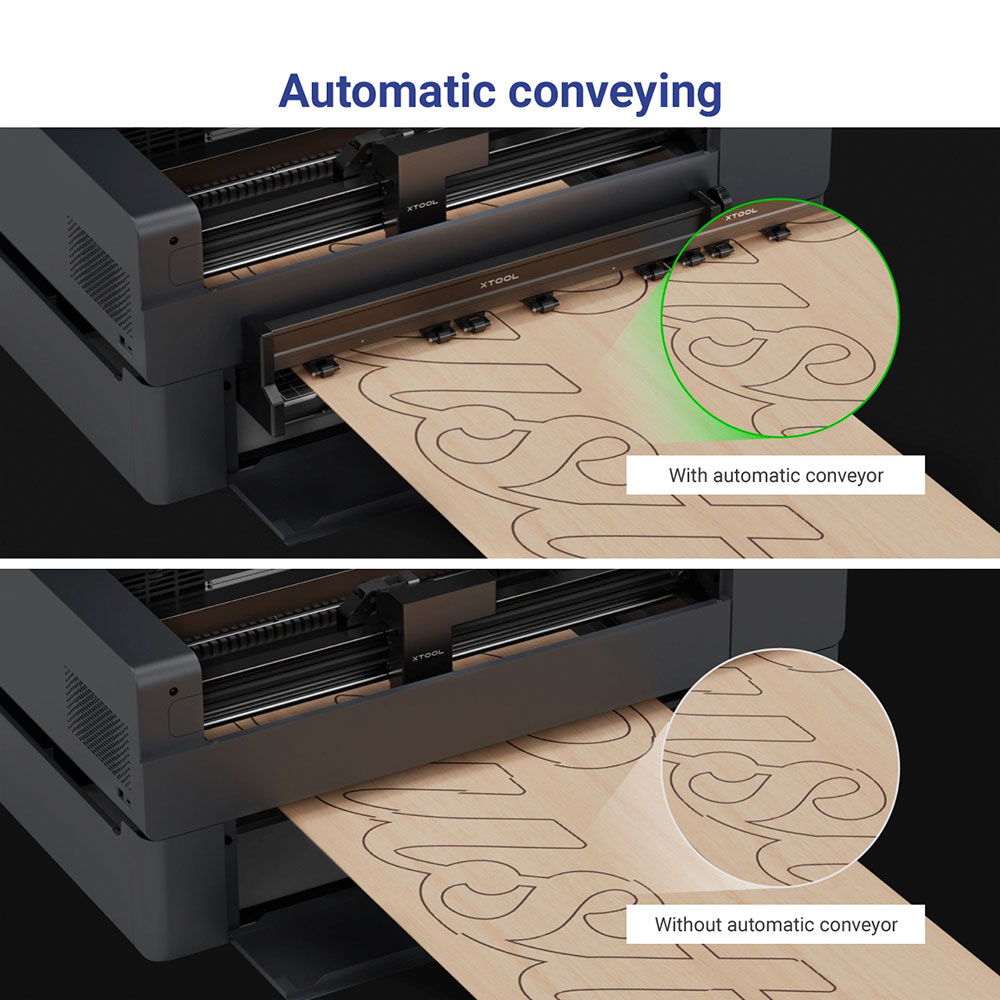

This conveyor device ensures that longer materials are automatically conveyed through the device. This increases the working area of your xTool P2 laser up to 3m x 44cm!

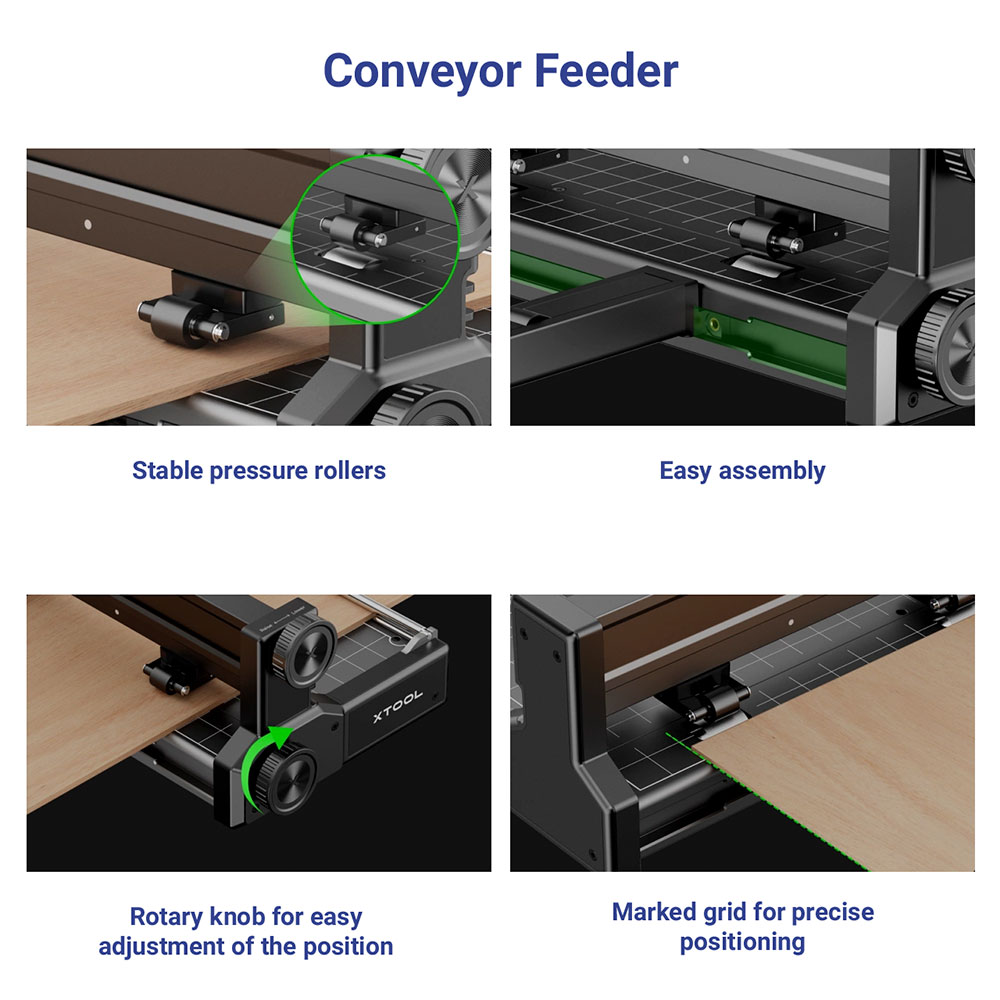

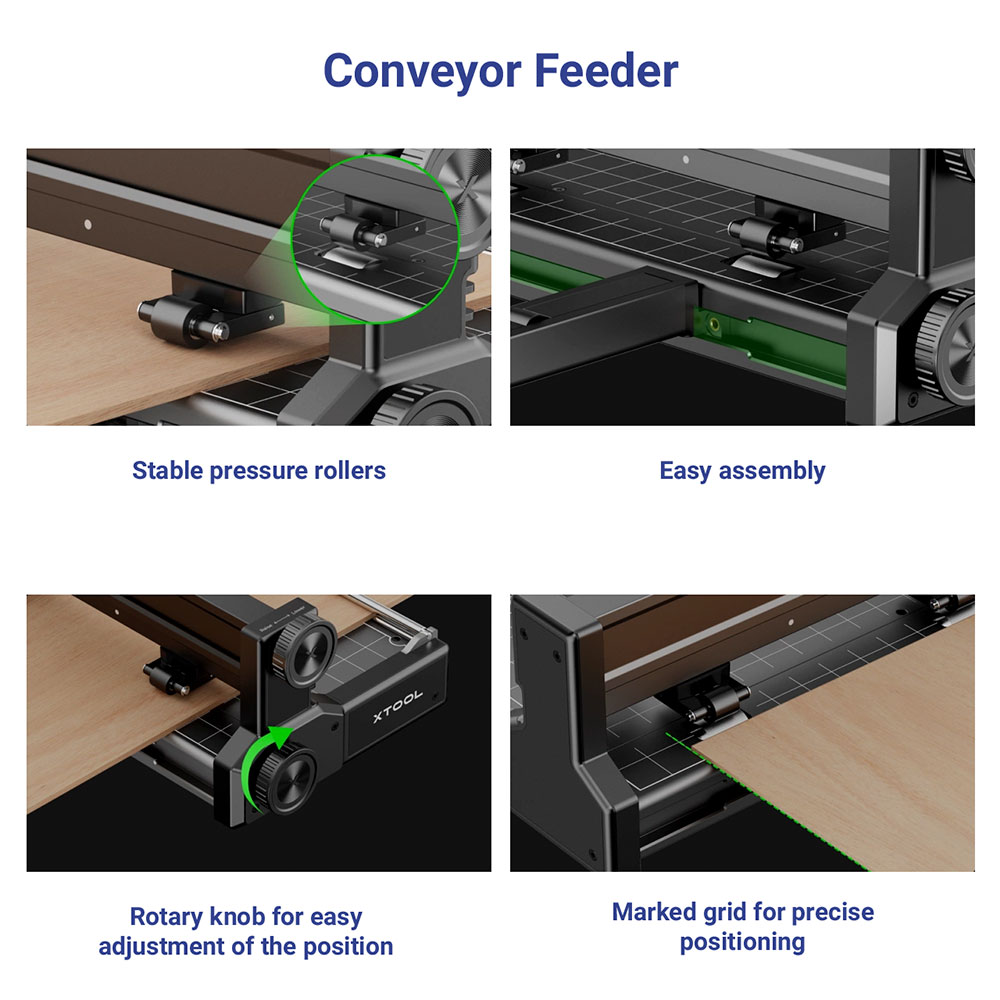

Thanks to the pressure rollers with anti-friction coating, the device automatically feeds your material so you don't have to push it through the machine by hand.

This allows you to achieve beautiful and large projects with consistent laser quality and no interruptions in your design.

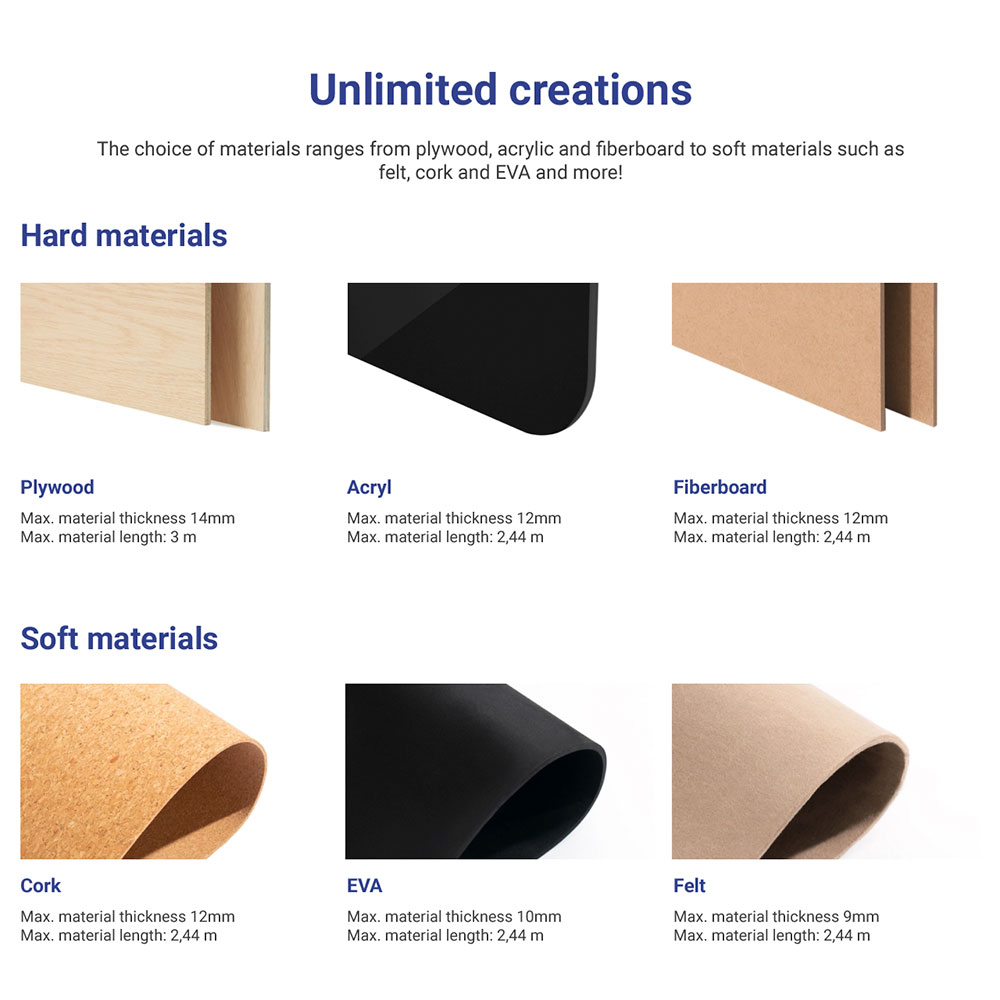

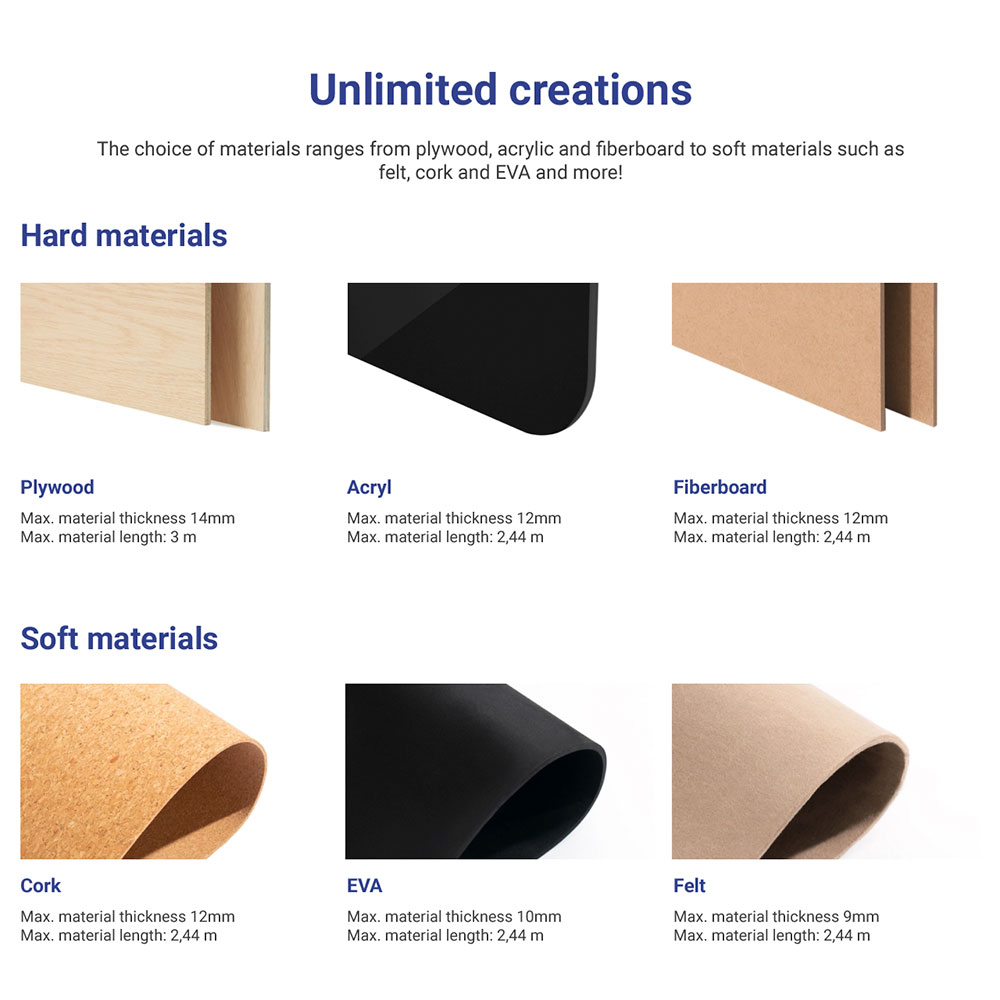

Material versatility

Process many materials such as spar wood, acrylic, fibreboard, cork, felt and much more.

User manual (multilingual, including German)

Notes: During processing, there may be a deviation of less than 2 mm per 1000 mm conveying distance.

Material compatibility varies, rigid materials recommended, flexible materials cannot be processed over the entire length.

The guide rails included in the scope of delivery are sufficient to process rigid materials of up to 1m in length (incl. 30cm overhang).

You can extend the length with the guide for conveyor device for xTool P2 CO2 laser (LK4). To reach the complete 3m, you need a total of three times the additional guide.

- 1x conveyor

- 4x guide rail incl. elevation

- Accessories and tools for assembly and use

The Makeblock success story began in 2012 when Jasen Wang, the founder and CEO, had a groundbreaking idea. As a passionate maker, Jasen realised how difficult it can be to turn a creative idea into reality. This drive gave rise to his first project: Makeblock.

Makeblock specialises in promoting STEAM education. The company helps young students develop their creativity by developing educational infrastructure - including robotics modules, coding software and laser cutters. The aim is to give pupils the tools to learn technical knowledge and creative skills through play.

At the end of 2020, Makeblock expanded its portfolio and entered the field of laser machines. With the xTool project, the product range was expanded so that not only students but also adults can benefit from the solutions. Creativity is not just about developing programming robots - it is also about personalising everyday objects, such as engraving names on mugs or creating works of art from wood.

With the launch of the first product, the xTool D1 in 2021, Jasen started a new chapter in his vision. While the Makeblock success story continues, xTool marks the start of an exciting new episode.

Contact:

MAKEBLOCK (HONG KONG) COMPANY LIMITED

19H Maxgrand plaza No.3 Tai Yau Street

San Po Kong, Kowloon, Hong Kong

European subsidiary

Makeblock Europe BV

Oostergracht 48, 3763 LZ Soest, Niederlande

Phone: +31 6 1264 5740

EMail: eu@makeblock.com

Register entries:

Registered with the Dutch Chamber of Commerce (KvK): 68916752

VAT no.: NL857646655B01